The SLOWPOKE-2 at RMC provides an intense neutron source used for teaching, training and research. It is currently used by researchers at RMC, Queen’s University, and the Department of National Defence. Some of the analytical applications that are made possible by the reactor include neutron activation analysis, neutron radiography, delayed neutron analysis, production of small amounts of short-lived radioisotopes and radiation processing.

Neutron Activation Analysis for trace metal composition

The stable thermal neutron flux produced by the SLOWPOKE-2 reactor is ideal for neutron activation analysis (NAA). In NAA, a neutron is absorbed by a nucleus in the target material. This results in the formation of a compound nucleus which, when radioactive, decays to a daughter nucleus. The daughter nucleus is generally left in an excited state and relaxes through the emission of characteristic X-rays and gamma rays. The energy of these photon emissions can be quantified and thus, the elemental composition of materials can be determined. The rate that the gamma rays are emitted from the material can also be quantified, which is directly proportional to the concentration of the element.

NAA is a gold standard American Society for Testing and Materials (ASTM) technique for elemental analysis and concentration quantification. It has advantages over other experimental techniques because:

- is non-destructive,

- it requires only a small amount of sample material (< 2mL),

- has very little sample preparation involved, and

- is able to perform multi-element identification efficiently, while having extremely sensitive detection limits (1 ng/g to 10 000 μg/g, depending on element).

NAA has been successfully used for the detection of trace elements in a variety of materials, including rocks, metals, plastics, organic matter, soils, and cement dust. For example, determination of protein contents in plants before and after genetic modification. It has been used for forensic analysis, for example, to analyse bullet lead fragments from the J.F. Kennedy assassination. It is also an excellent technique for ancient artifact analysis, e.g., what types of materials were used for clay pots which can be a clue for culture contact at the time.

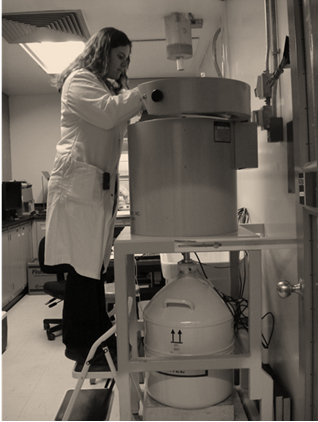

NAA instrument, where the large cylindrical contains the sample and the germanium crystal detector.

Neutron Radiography for non-destructive imaging

Neutron radiography is a non-destructive imaging technique. It works in a similar manner as X-ray imaging, where the sample is exposed to neutrons and a detector (on the opposite side of the sample) produces an image of the internal structure of the object. Neutron radiography is preferred over X-ray imaging when low-density materials must be differentiated, but the two techniques are often used complimentary to each other.

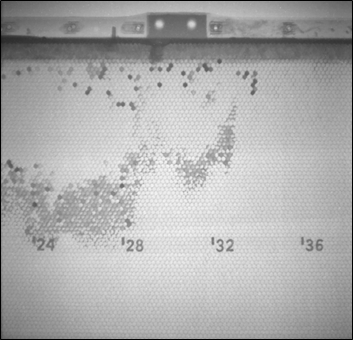

Neutron radiography is often used to determine the location or follow the movement of water in materials. For example, researchers at RMC determined the amount of water ingression into the internal honeycomb structure of a CF-188 wing to determine the amount of internal stress and corrosion that the plane will be exposed to in different flying conditions.

Neutron radiography has been improved and tomography is now possible at RMC. Samples are imaged as they rotate and post-experimental processing allows a 3D image to be produced. Tomographic images provide more spatial awareness to the analysis. For example, it has been used to non-destructively observe an Ancient Egyptian bronze statue.

Water ingress in a CF-188 rudder (Image courtesy of Major Paul Hungler)

Water ingress in a CF-188 rudder (Image courtesy of Major Paul Hungler)

Delayed Neutron Counting System for uranium and plutonium quantification

RMC scientists have an ultra-sensitive Delayed Neutron Counting (DNC) system for detection of special nuclear materials. An array of 3 He detectors and a high purity germanium detector (HPGe) record neutron and gamma emissions from irradiated fissile material as a function of time to accurately determine concentrations of uranium and plutonium. DNC is used in the uranium mining industry to determine the concentration of uranium in soils with a very high degree of accuracy. It is also used in nuclear forensic analysis for safety, monitor, and investigation of nuclear devices.

Radiation Processing for material creation and testing

Radiation processing involves irradiating materials with high energy particles for modification and synthesis of materials and for testing material properties (e.g., corrosion or mechanical strength).

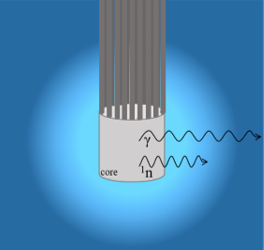

Thanks to the open pool concept, the SLOWPOKE-2 at RMC can be used for radiation processing using a mixed neutron-gamma field, as shown in the schematic on the right. Samples are sealed in air-tight vials and placed in an area within the core or in the pool, depending on the desired neutron-to-gamma-ray ratio.

At the RMC, radiation processing has been primarily used for polymers, polymer-based adhesives and polymer-based composite materials. The mixed radiation field in the reactor pool was used to improve the adhesive properties in materials used in space vehicles. It has also been used to improve the strength of polymer materials, including PolyEtherEtherKetone (PEEK) and PolyEtherImide (PEI), which are being considered to fabricate nuclear waste disposal containers. The mixed radiation field is also used by RMC researchers to determine corrosion rates of materials used in nuclear reactors.

Schematic representation of the mixed radiation field in the pool environment.

Recent Publications

- Characterization of flux distribution in the pool of the RMC SLOWPOKE-2

- Advanced MCNP Simulation of the Neutron and Photon Flux and Absorbed Dose Rates for the SLOWPOKE-2 Nuclear Reactor at the Royal Military College of Canada

- Reactor power monitoring using Cherenkov radiation transmitted through a small-bore metallic tube

- The production of Ar-37 using a thermal neutron reactor flux

- MCNP6 simulations of gamma line emissions from fission products and their comparisons to plutonium and uranium measurements